PRODUCTS

Contribute to the world with high-quality products

We offer a wide range of industrial products, from industrial burners to auxiliary equipment,heat treatment furnaces, and labor-saving machines.We have a large number of our own products and provide total support to our customers,from planning and design to manufacturing. We have a consistent production system.

Industrial gas burner

Straight flame / Direct frame type

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

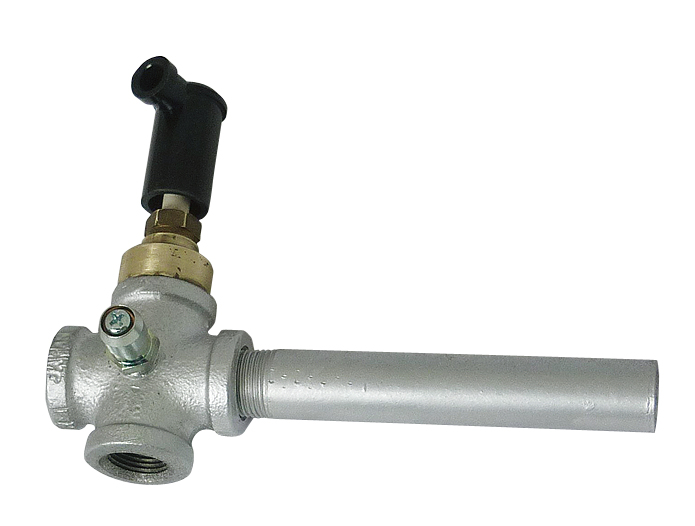

| Name | Pilot burner |

|---|---|

| Model | PLM・PLL |

| Flame type | Straight flame |

| Product code | PLL-5K PLL-10K PLL-20K PLM-5K PLM-10K PLM-20K |

| Features | Source mixing burner which can be used independently or as a pilot. |

| Use | Burner for ignition (pilot burner) |

| Combustion amount | 5.1kW~20Kw |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

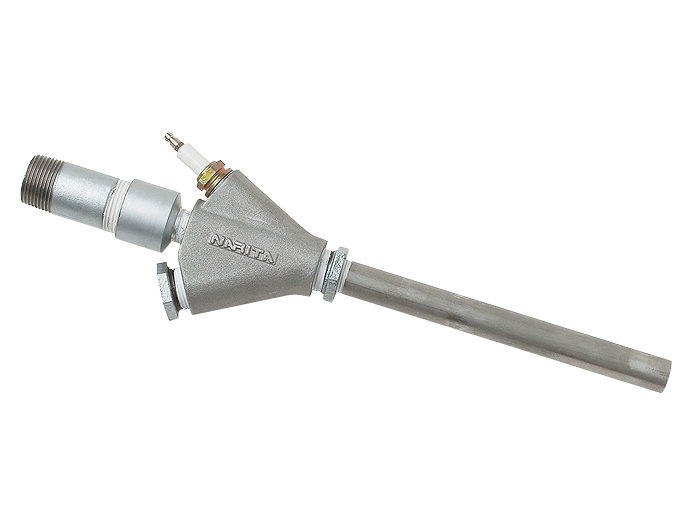

| Name | Swirled short flame pilot burner |

|---|---|

| Model | PLS |

| Flame type | Straight flame |

| Product code | PLS-2K PLS-5K PLS-10K PLS-20K PLS-40K |

| Features | The combustion range is wide compared to the source mixing burner with a flame retention structure. It is difficult to blow its strong flame off. It has an excellent ignition performance. Even if the air ratio changes and is increased, the burner recovers to produce its excellent flame when the air ratio returns to normal. |

| Use | Burner for ignition (pilot burner) |

| Combustion amount | 2.0kW~41Kw |

| Name |

Pilot burner

Catalog

|

|---|---|

| Model | NPU |

| Flame type | Straight flame |

| Product code | NPU-20/15A NPU-20/20A |

| Features | It is a source mixing burner which can be used independently or as a pilot. The burner body is made of aluminum alloy and so is lightweight. The burner top length can be specified freely. |

| Use | Burner for ignition (pilot burner) |

| Combustion amount | 5.2kW~11kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | High Temp Burner |

|---|---|

| Model | HT |

| Flame type | Straight flame |

| Product code | HT-50K HT-100K HT-200K HT-500K |

| Features | It can be used in ranges from low temperature to 1400°C. Stable combustion can be achieved over a wide range of air ratios. The working gas pressure is low and appliances such as a booster machine are not necessary. The turn-down ratio is high. |

| Use | Forging and heating of steel, heating of steel and copper alloy, hardening and tempering of steel, porcelain firing Enamel firing, non-ferrous metal pot furnaces, and other general heating furnaces |

| Combustion amount | 52kW~525kW |

Straight flame

Straight flame

| Name | HAM burner |

|---|---|

| Model | HAM |

| Flame type | Straight flame |

| Product code | HAM-50K HAM-100K HAM-200K HAM-100KR HAM-200KR |

| Features | It can be applied to various industrial furnaces from low to high temperature ranges. Tempered air up to 400°C can be used. An excellent furnace air mixing effect can be obtained with a straight flame. It has a high turn-down ratio and can be used with a low pressure supply. High-speed bottleneck specifications are also available. |

| Use | Heating furnace for casting, non-ferrous metal melting furnaces, and heat treatment furnaces |

| Combustion amount | 52kW~210kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name |

LC burner

Catalog

|

|---|---|

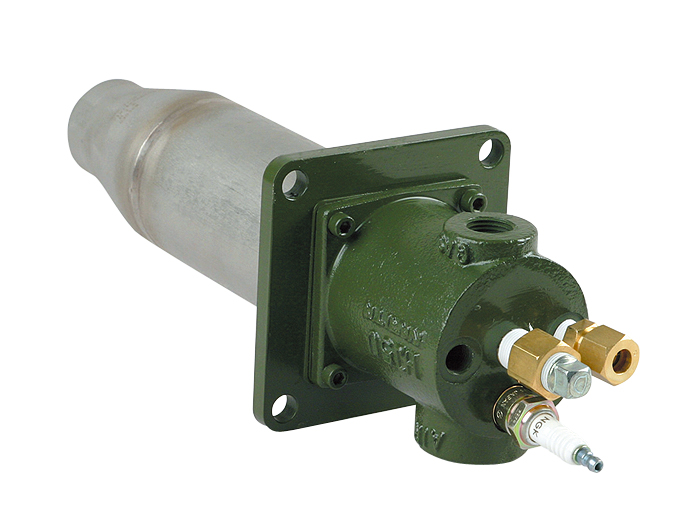

| Model | LC |

| Flame type | Straight flame |

| Product code | LC-20K-S LC-50K-S LC-100K-S LC200K-S LC-400K-S LC-800K-S LC-1600K-S LC-20K-L LC-50K-L LC-100K-L LC-200K-L LC-400K-L LC-800K-L LC-1600K-L |

| Features | It is a lightweight and compact burner since aluminum alloy is used for the burner body. It generates a short flame. The flame diameter is further reduced by narrowing the end of the heat chamber, and the flame length is also shortened. The flame diameter and length can be adjusted according to the features of the equipment (type S). The flame diameter is comparatively small and long (type L). For 20K to 800K, the main burner is ignited directly. Thus, pipes around the burner can be arranged easily. Preheated air up to 300°C is usable. |

| Use | Heating furnaces, crucible type non-ferrous metal melting furnaces, pot type metal heat treatment furnaces, and ladle heating equipment |

| Combustion amount | 21kW~1679kW |

| Name | Metallic jet burner |

|---|---|

| Model | MJ |

| Flame type | Straight flame |

| Product code | MJ-50K MJ-100K |

| Features | Since a metal heat chamber is used, the burner is lightweight and compact. It can be installed at the desired angle. A direct ignition method is used. |

| Use | Non-ferrous metal melting furnaces, drying furnaces, metal heat treatment furnaces, and other heating furnaces |

| Combustion amount | 52kW~104kW |

| Name |

Metallic burner

Catalog

|

|---|---|

| Model | MJP |

| Flame type | Straight flame |

| Product code | MJP-20K MJP-50K MJP-100K MJP-200K MJP-400K |

| Features | Since a metal heat chamber is used, it is lightweight and compact, and can be installed at the desired angle. The combustion range is wide during low combustion and it can be used even when excess air is supplied. A direct ignition method is used. |

| Use | Non-ferrous metal melting furnaces, drying furnaces, metal heat treatment furnaces, and other heating furnaces |

| Combustion amount | 21kW~420kW |

| Name |

High jet burner

Catalog

|

|---|---|

| Model | HJ |

| Flame type | Straight flame |

| Product code | HJ-15K HJ-50K HJ-100K HJ-200K |

| Features | The burner body is lightweight and compact. It can be used within ranges from low temperature to 1800°C. A direct ignition method is used. |

| Use | Heating furnace for forging, non-ferrous metal melting furnaces, ceramic firing furnaces, metal heat treatment furnaces, and other heating furnaces |

| Combustion amount | 15kW~207kW |

.jpg)

| Name |

High jet burner (H-L control specifications)

Catalog

|

|---|---|

| Model | HJP |

| Flame type | Straight flame |

| Product code | HJP-100K HJP-200K HJP-400K |

| Features | The burner body is lightweight and compact. There are long flame specifications and short flame specifications, and they can be used for various purposes. A direct ignition method is used. |

| Use | Heating furnace for forging, non-ferrous metal melting furnaces, drying furnaces, metal heat treatment furnaces, and other heating furnaces |

| Combustion amount | 21kW~420kW |

.jpg)

| Name |

High jet burner(with dilution air)

Catalog

|

|---|---|

| Model | WHJ |

| Flame type | Straight flame |

| Product code | WHJ-50K WHJ-100K WHJ-200K |

| Features | Dilution air can be introduced from another system based on our high jet burner. Heating and cooling of dilution air and gas combustion can be controlled easily. A direct ignition method is used. |

| Use | Ceramic firing furnaces and other heating furnaces |

| Combustion amount | 52kW~207kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | BF burner |

|---|---|

| Model | BF |

| Flame type | Straight flame |

| Product code | BF-200K BF-400K BF-800K |

| Features | It is a compact burner which can generate a luminous flame equal to that produced by an oil burner by thermally decomposing natural gas. Preheated air up to 450°C is usable. Since a direct ignition method is used, the pipe arrangement is simple. The turn-down ratio is high. (10:1) |

| Use | Heating furnace for forging, metal melting furnaces, and heat treatment furnaces |

| Combustion amount | 207kW~842kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

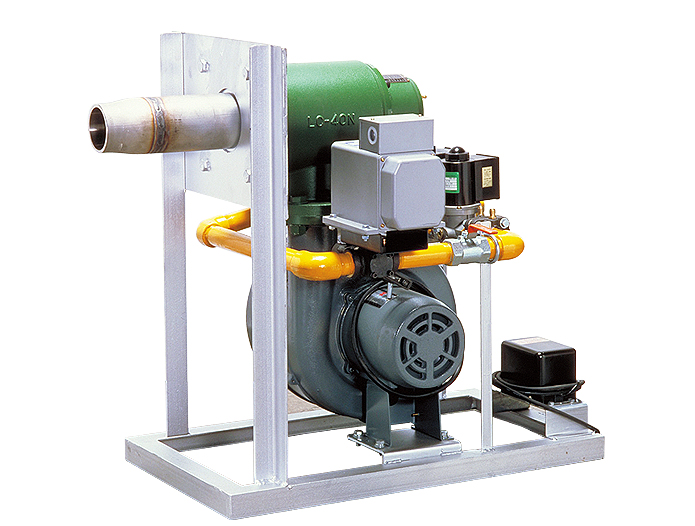

| Name | LC burner with fan |

|---|---|

| Model | LCF |

| Flame type | Straight flame |

| Product code | LCF-50K-L LCF-100K-L LCF200K-L LCF-400K-L LCF-800K-L LCF-50K-S LCF-100K-S LCF200K-S LCF-400K-S LCF-800K-S |

| Features | Since it is a package type of product, it can be set up easily at the site and is available for a low price. Both long flames and short flames can be selected from among 52 to 840 Kw, and various types of equipment and applications are supported. Temperature can be controlled sensitively through its high turn-down ratio. Since the fan pressure is high, it can be used even in equipment that uses a positive furnace pressure. |

| Use | Heating furnace for forging, non-ferrous metal melting furnaces, drying furnaces, metal heat treatment furnaces, and other heating furnaces |

| Combustion amount | 52kW~840kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | MK burner |

|---|---|

| Model | MK |

| Flame type | High-speed straight flame |

| Product code | MK-80K MK-150K MK-300K MK-500K |

| Features | The flow velocity of the combustion gas is 180 m/s, which is high speed. It is lightweight since it uses a metal heat chamber. The mixing effect in the furnace is increased by the high-speed exhaust stream. The convection heating effect is increased by the high-speed exhaust stream. |

| Use | Heat treatment furnaces, heating furnaces, galvanizing furnaces |

| Combustion amount | 84kW~525kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | RO burner |

|---|---|

| Model | RO |

| Flame type | High-speed straight flame |

| Product code | RO-30K RO-50K RO-100K RO-200K RO-400K RO-600K |

| Features | It can be operated in air ratios ranging from 0.7 to 1.0. The turn-down ratio is high. (5:1) There is no need to worry about backfire and the safety level is high. A nozzle mixing method is basically used for the burner structure. The burner top contains a section for mixing combustion gas and air. The remaining oxygen concentration in the combustion gas becomes nearly zero by carefully mixing the gas. The amount of carbon precipitation is also small. |

| Use | Heat generation atmosphere gas generators, non-metallic melting/holding furnaces Copper bright annealing furnaces and others (scale furnaces etc.) |

| Combustion amount | 31kW~629kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | Bunsen burner using gas pressure |

|---|---|

| Model | SBB |

| Flame type | Straight flame |

| Product code | SBB-20K SBB-50K SBB-150K SBB-300K SBB-600K |

| Features | Air is taken in from the primary air suction hole provided on the nozzle tip and burner body by means of gas pressure (98 Kpa as standard), mixed in the mixing tube, and blown out of it. Then, secondary air is taken in from the end of the heat chamber and burned. Since an air blower for combustion is unnecessary, the periphery of the burner is streamlined. The burner can be installed and removed easily and can also be easily operated (ignited and extinguished). The burner is simple and low cost. It is easy to maintain. |

| Use | Non-ferrous metal heating, ladle and steep plate heating, heating of various molds |

| Combustion amount | 20kW~635kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | Compressor air burner |

|---|---|

| Model | COM |

| Flame type | Straight flame |

| Product code | COM-20K COM-50K COM-150K COM-300K COM-600K |

| Features | The COM burner uses high-pressure air as part of the combustion air source and burns air in the atmosphere using that pressure. No combustion blower is needed. It can be easily operated (ignited and extinguished). |

| Use | Non-ferrous metal heating, ladle and steep plate heating, heating of various molds |

| Combustion amount | 20kW~635kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | Two-staged combustion burner for low Nox |

|---|---|

| Model | PAX |

| Flame type | Straight flame |

| Product code | PAX-200K PAX-400K |

| Features | It has a structure which does not create a local high-temperature area in the flame by combining the two-staged combustion method and self- recirculation method. The low Nox level can be maintained even if the combustion air is preheated up to 300 to 400°C. |

| Use | Heat treatment furnace, heating furnace |

| Combustion amount | 210kW~420kW |

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

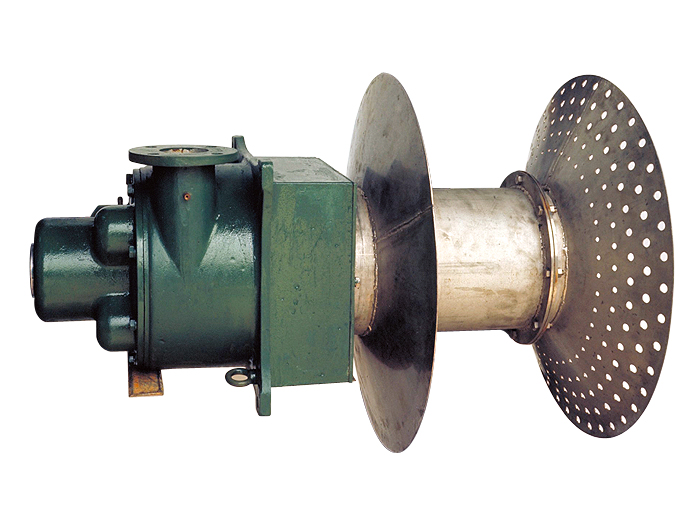

| Name | Submerged combustion burner |

|---|---|

| Model | SM |

| Flame type | Straight flame |

| Product code | SM-150K SM-240K SM-350K SM-800K |

| Features | A high heat efficiency can be obtained by direct vapor heat exchange. It has a fluid mixing effect through jet flow of the combustion gas. A baffle plate is used to prevent any whirling motion on the liquid surface, improve the efficiency, and realize a quiet combustion. |

| Use | Liquid tank heating, condensation of chemical, waste liquid, bath, heated pool |

| Combustion amount | 150kW~800kW |

| Name | Source mixing line burner |

|---|---|

| Model | ML |

| Flame type | Line flame |

| Product code | ML-3U.6U.9U12U.15U |

| Features | It is made of cast iron, which is robust and durable. |

| Use | Low-temperature heating equipment |

| Combustion amount | 31KW~154KW |

| Name |

NCL burner

Catalog

|

|---|---|

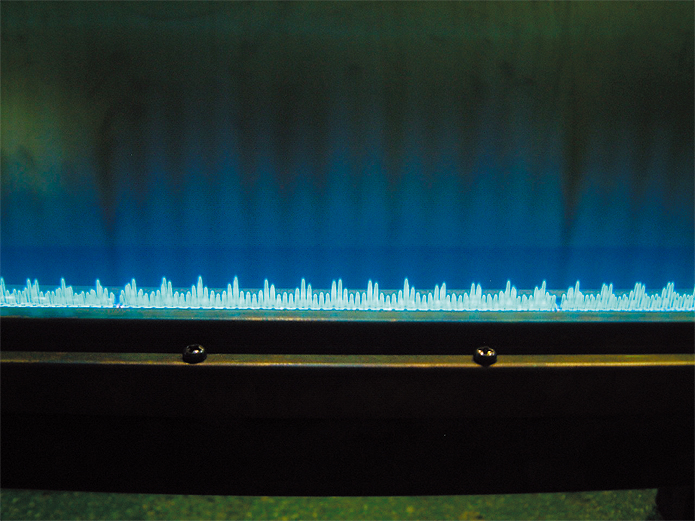

| Model | NCL |

| Flame type | Line flame |

| Product code | NCL-4 NCL-6 NCL-8 |

| Features | This line burner uses a ceramic plate as the combustion plate. Since the turn-down ratio is high, uniform and stable combustion is available from radiant heating by surface burning to convection heating by a blue flame. |

| Use | Band ovens, hot-air drying furnaces, fryers for industrial use |

| Combustion amount | 14kW~27.9kW |

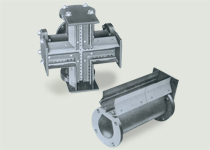

| Name | Induction burner |

|---|---|

| Model | CBI.CBX |

| Flame type | Line flame |

| Product code | CBI-7.5. CBX-15 |

| Features | Hot air from a direct flame can be generated by installing the burner in a ventilation duct. It is a unit type of air heating burner (can be coupled in units of 300 mm). |

| Use | It is used for hot air generators. No pilot burner is needed. |

| Combustion amount | CBI 87KW・CBX 174K |

Flat flame / Direct frame type

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

| Name | Flat flame burner |

|---|---|

| Model | FF |

| Flame type | Flat flame |

| Product code | FF-20K FF-40K FF-60K FF-130K |

| Features | Since the flame spreads thinly around, proximity heating can be performed and the equipment can become compact. The turn-down ratio is high. There is no specified direction in which the burner should be mounted. Since even excess air burns, the burner can be used in both high-temperature and low-temperature ranges. |

| Use | Hardening and tempering of steel, heating of steel for casting Annealing of steel or aluminum alloy, dissolution of low-melting-point metal |

| Combustion amount | 24kW~144kW |

| Name | Metallic flat flame burner |

|---|---|

| Model | FFM |

| Flame type | Flat flame |

| Product code | FFM-20K FFM-40K FFM-60K FFM-130K |

| Features | Since it is metallic, it is lightweight, robust, and compact. Since the flame spreads thinly around, proximity heating can be performed and the equipment can be compact. The turn-down ratio is high. There is no specified direction in which the burner should be mounted. Since even excess air burns, the burner can be used in both high-temperature and low-temperature ranges. |

| Use | Hardening and tempering of steel, heating of steel for casting Annealing of steel or aluminum alloy, dissolution of low-melting-point metal |

| Combustion amount | 24kW~144kW |

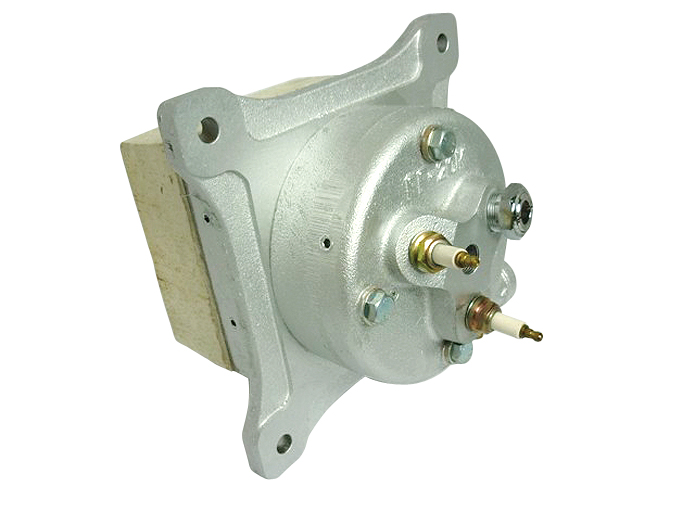

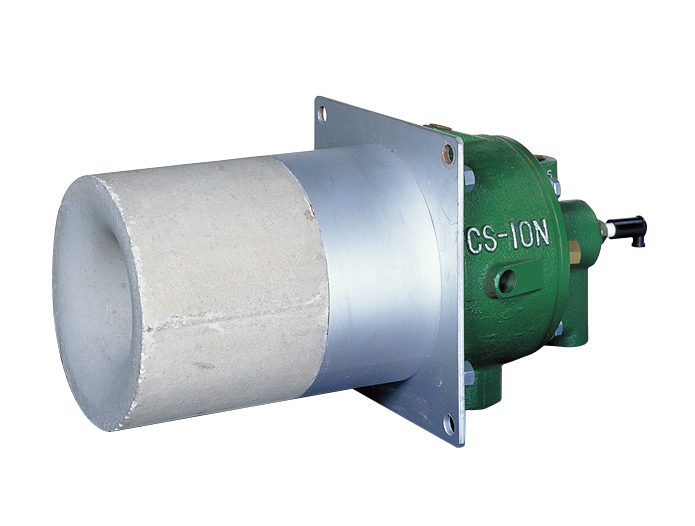

| Name | CS burner |

|---|---|

| Model | CS |

| Flame type | Flat flame |

| Product code | CS-100K CS-200K CS-400K |

| Features | It is a flat flame burner with a long tile. It can be easily attached to a high-temperature furnace with a thick furnace wall. The turn-down ratio is high. (6:1 or more) The burner is compact. Preheated air up to 300°C can be used. |

| Use | Metal heat treatment furnaces, non-ferrous metal melting furnaces, casting furnaces, independent glass furnaces |

| Combustion amount | 104Kw~415Kw |

Indirect heating

Developed by Osaka Gas and manufactured by us

Developed by Osaka Gas and manufactured by us

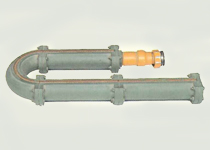

| Name |

radiant tube burner

Catalog

|

|---|---|

| Model | RTN |

| Flame type | Straight flame indirect radiant type |

| Product code | RTN-80A-S RTN-100A-S RTN-125A-S RTN-80A-L RTN-100A-L RTN-125A-L |

| Features | No vibration or noise is produced regardless of the inner diameter and shape of the radiant tube and whether or not heat exchange is performed. Thus, excellent combustion can be achieved. There are short flame specifications and long flame specifications, and they can be used for various purposes. It can be used with direct ignition and ON/OFF control of the time proportion, and can be adjusted easil |

| Use | Heat treatment furnaces, drying furnaces |

| Combustion amount | 42kW~84kW |

Burner developed by Osaka Gas and manufactured by us

Sales: Creative Techno Solution Co., Ltd.

Manufacturing and sales: Narita Seisakusho Co., Ltd.